A CNC machining centre takes instructions from a computer file, using instructions to select and control tools that carve a block of metal, or billet, into a new product. Using this machine ensures that every product built to the same instructions will be identical.

While this guidance has not been updated to reflect current work health and safety legislation (the Health and Safety at Work Act 2015 and regulations), it may still contain relevant information and practices to keep workers and others healthy and safe.

Please read this guidance in conjunction with all relevant industry standards that apply to you as a PCBU. This guidance will be progressively reviewed and either updated, replaced with other guidance, or revoked.

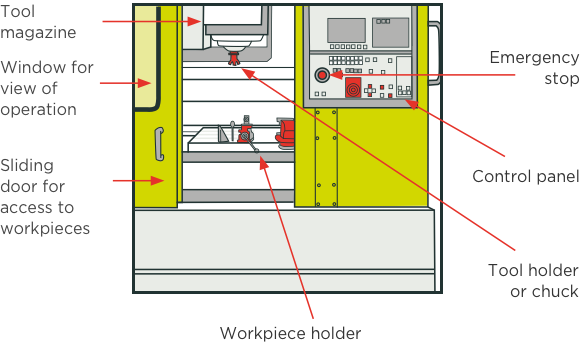

The metal is securely clamped in a workpiece holder. Tools picked from a magazine (sometimes set up as a carousel) are securely fixed in a tool holder and used to carve a shape from the metal.

Figure 1: CNC machine

Hazards

- Contact, impact or entanglement from moving parts/unwanted movement

- Contact or impact from accidentally released tools

- Contact with metal chips or swarf

- Contact with liquid coolant

- Slips, trips and falls

- Trapping, impact or entanglement from unexpected movement (during maintenance, cleaning & repairs)

Personal protective equipment (PPE)

- Ear protection

- Eye protection

- Face protection

Tasks

Task – Load/unload materials

Hazard

Contact, impact or entanglement from moving parts/unwanted movement

Harm

- Bruising

- Cuts or amputation

Controls

- KEEP the door interlock running to prevent operation while the workpiece is secured.

- When a new programme is tried, and the door is open, speed of operation MUST be slow.

Task – Machining centre process (securing workpiece, tool selection, shaping workpiece)

Hazard

Contact or impact from accidentally released tools

Harm

- Bruises

- Cuts or amputation

- Death

Controls

- USE tools at appropriate speeds.

- ENSURE that the tools and workpiece can move when the door is securely closed.

Tools may accidentally release from the holder when revolving at speed, and the tool may pierce the viewing window or the steel guard. Operator error and poorly maintained revolving parts may allow a part to eject. When steel bars are added to supplement the vision panel, the bars MUST be spaced to keep all ejected tools contained.

Hazard

Contact with metal chips or swarf

Harm

- Burns or skin damage

Controls

- KEEP chips of metal contained.

Other (non-mechanical) hazards

Hazard

Contact with liquid coolant, including aerosols

Harm

- Breathing difficulties and skin damage

Controls

- ENSURE that cooling fluids and lubricants are:

- CONTAINED to prevent harm

- TREATED or replaced in accordance with manufacturer’s instructions.

Fluids and lubricants used in the machining process degrade strength of polycarbonate viewing panels by about 10% per year.

Hazard

Slips, trips and falls

Harm

- Cuts

- Bruising

- Contact or impact injuries

Controls

- KEEP up-to-date housekeeping procedures.

- KEEP the area around machines clear of slip and trip hazards.

Task – Maintenance, cleaning & adjustments

Hazard

Trapping, impact or entanglement caused by unexpected movement

Harm

- Bruising

- Cuts or amputation

- Death

Controls

- LOCK-OUT all power supplies before maintenance, cleaning or adjustments.

- KEEP the door interlock running to prevent operation.

- Employers should ARRANGE and RECORD daily safety checks, as well as regular inspections by a competent person.

- REMOVE or LOCK-OUT machines that fail inspection, and DO NOT USE until repaired or replaced.

- Grilles and vision panels MUST be sufficiently sized and maintained to prevent tools from being thrown.

- UNDERTAKE a hazard analysis when CNC is added to control operations on an older manual machine.

If an inspection shows limited ability to contain thrown parts, and an upgrade doesn’t happen, speed or weight of turning parts MUST be restricted to a safe level. When adding CNC to an older machine, machine parts can move more rapidly, and greater volumes of aerosols from metalworking fluids can be released.

Download fact sheet

Last updated